|

| March 28, 2023 | Volume 19 Issue 12 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Ford teases new electric truck, touts new mega-factory

BlueOval City, Ford's all-new mega-campus in West Tennessee, is taking shape and preparing to build Ford's next-gen electric truck, code named Project T3, in 2025. Site shown as of March 10, 2023. [Credit: Ford Motor Co.]

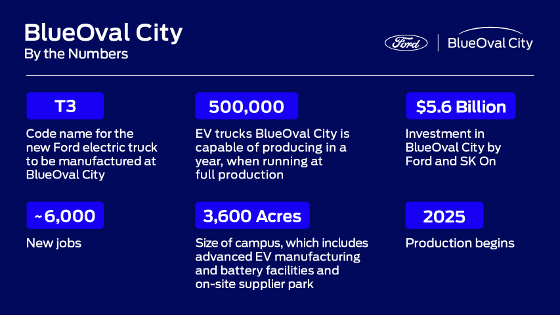

Ford was filled with updates on Friday, March 24, 2023, including teasing a second-generation electric truck (code named Project T3) for 2025 and giving a progress report on its BlueOval City vehicle and battery manufacturing mega-campus being built in West Tennessee. The company aims for the facility to produce 500,000 electric trucks a year at full production, with first vehicles rolling out of the facility in 2025. Ford is targeting a production run rate of 2 million electric vehicles (EVs) annually across the globe by late 2026.

"BlueOval City is the blueprint for Ford's electric future around the world," said Bill Ford, Ford's executive chair. "We will build revolutionary electric vehicles at an advanced manufacturing site that works in harmony with the planet, aligning business growth and innovation with environmental progress."

Ford and partner SK On are investing $5.6 billion in the campus and creating approximately 6,000 new jobs. Ford has launched a comprehensive education and training effort called BlueOval Learning to prepare future employees. BlueOval City is also designed to be Ford's first carbon-neutral vehicle manufacturing and battery campus, as Ford works to power all Ford plants globally with renewable and carbon-free electricity by 2035.

Project T3 -- viewed as "new industrial era" by Ford

Ford's Project T3 aims to further grow and reinvent the Ford truck franchise after the unveiling of the F-150 Lightning all-electric pickup truck in May 2021.

Ford is developing its second-generation EV truck in tandem with the all-new assembly plant and hoping to reap the benefits of increased efficiencies along the way, such as a 30% smaller general assembly footprint than traditional plants that can still deliver a higher production capacity.

"PJ O'Rourke once described American pickups as 'a back porch with an engine attached.' Well, this new truck is going to be like the Millennium Falcon -- with a back porch attached," said Jim Farley, Ford president and CEO.

Project T3 is short for "Trust The Truck," which is a code name that stuck after the Ford development team made it their rallying cry. The team's single guiding principle has been to create a truck people can trust in the digital age -- one that's "fully updatable, constantly improving, and supports towing, hauling, exportable power, and endless new innovations owners will want." No other details on the new truck were released, which is a bummer.

The assembly plant, however, is full of innovation. It will use carbon-free electricity from the day it opens. For the first time in 120 years, Ford is also using recovered energy from the site's utility infrastructure and geothermal system to provide carbon-free heat for the assembly plant, saving about 300 million cubic ft of natural gas typically needed each year to heat similarly sized vehicle assembly plants.

BlueOval City rendering: Designed to be radically efficient and carbon neutral, the truck plant on the BlueOval City site will be capable of producing 500,000 electric trucks a year at full production. [Credit: Ford Motor Co.]

The campus' new utility system is projected to save 50 million gallons of water each year by reducing evaporation from the site's cooling towers. Plus, the zero-waste-to-landfill site is designed to use no fresh water for its assembly processes. Ford also intends to develop a holistic storm water management system separate from the water table to help protect the local environment.

The 3,600-acre campus also has a fully integrated BlueOval SK battery manufacturing site. On-site, the team will build battery cells and arrays and assemble battery packs that will be delivered just across the site into the assembly plant in less than 30 minutes.

BlueOval City by the numbers. [Credit: Ford Motor Co.]

In addition, BlueOval City is developing an on-site supplier park and will have an upfit center capable of adding in dozens of Ford trucks' most popular features, including robotically installed spray-in bedliners and integrated tool boxes before the pickups are released to dealers and customers.

To help reduce traffic congestion and emissions, the campus also will have an on-site Lowe's store supplying building materials, two construction equipment rental companies, and three concrete batch plants.

Efforts to build tomorrow's workforce

To prepare individuals for new jobs at BlueOval City, Ford is introducing a program called "BlueOval Learning" to empower future workers to build an EV future in America. This talent development program aims to strengthen skills, provide teacher support, and increase work-based learning experiences. Key elements include:

- Building STEM curricula: Ford will support K-12 schools and universities to expand existing STEM-related curricula and infrastructure;

- Bringing advanced manufacturing to local schools: Ford will provide mechatronics training equipment and program development in Haywood, Tipton, and Lauderdale counties in Tennessee;

- Kick-starting careers in high schools: Ford will help to expand certifications and dual-enrollment opportunities for students;

- Experiential learning: Ford will partner with colleges and universities to develop work-based learning such as co-ops and internships;

- Premier training in advanced technologies: Ford will collaborate with higher education institutions to provide training on advanced manufacturing, EVs, and battery manufacturing; and

- BlueOval City TCAT: This state-of-the-art training center, a $40 million investment by the state of Tennessee and created with the Tennessee Colleges of Applied Technology, will be a hub for education resources and best-in-class training programs.

For more about employment at BlueOval City, visit https://corporate.ford.com/operations/blue-oval-city/tennessee.html.

Source: Ford Motor Co.

Published March 2023

Rate this article

View our terms of use and privacy policy